Core-Shell Particles

Caution: Since the colloid synthesis is sensitive

to various laboratory conditions and the practices of the individual

researchers, the following procedure should be taken as a general

guideline. One may have to vary the experimental conditions to suit

their needs.

- Gold Capped

Silica/Alumina

Collods

- Gold Capped

TiO2

Collods (TiO2@Au)

- Ag @TiO2 and Ag@SiO2

Colloids.

Gold Capped

Silica/Alumina

Collods

Nalco Chemicals markets alumina capped silica colloids that are stable

in acidic pH. These colloids are positively charged and

electrostatically bind to [AuCl4]-

ions

- Prepare 10mM HAuCl4 solution

(0.0985g in 25mL of H2O).

- Add 20 mL of the 10 mM HAuCl4

solution dropwise with vigorous stirring to 20mL solution of 10% SiO2/Al2O3

solution in water (2mL of SiO2/Al2O3 in 20 mL of H2O).

I used a solution consisting of 3.8 (w/w)% Al2O3 and 19 (w/w)% SiO2.

- Add sodium borohydride solution in water (~10mM) dropwise with

vigorous stirring until a color change from pale yellow to dark purple

occurs.

See reference, Dawson, A; Kamat, P. V. J. Phys. Chem. B.

2000, 104,11842-11846

Gold Capped TiO2

Collods (TiO2@Au)

5mM TiO2 Colloids:

- Prepare 10% titanium(IV) isopropoxide in 1-propanol (or

isopropanol):

Dilute 2.5mL of titanium(IV) isopropoxide in 25mL of 1-propanol.

- Prepare 5mM TiO2:

2.97mL of 10% titanium(IV) isopropoxide diluted in 200mL of water.

pH of water was adjusted to 1.5 using 1M HClO4

prior to addition, to stabilize TiO2 colloids.

**IMPORTANT: Add titanium isopropoxide solution slowly,

1 drop at a time, while stirring vigorously, to obtain a clear,

colorless solution.

- Store in a stoppered flask and use freshly prepared.

Note: I was able to make TiO2

colloids of concentrations of up to 15mM. Higher concentrations were

less stable and the resulting solutions were whitish and cloudy (not

suitable for absorption measurements).

5mM HAuCl4:

- Dissolve 0.1697g of HAuCl4 in

100mL water.

TiO2@Au Colloids:

- Add desired volume of Au dropwise to TiO2

colloids while stirring vigorously, to obtain desired concentration.

- I generally worked with [TiO2] of 2-4mM and

[Au] of 0.06-0.3mM

- Note:

For very low [TiO2] or very high [Au]

(with respect to TiO2) then the colloids are

unstable.

- Stir for 5-10 min (to allow all gold to adsorb to TiO2 surface).

BH4- Reduction:

- Prepare ~10 mM NaBH4 in water

(use 1mM when TiO2 concentration is low to avoid

aggregation effects):

0.0095g NaBH4 dissolved in 25mL

of water.

- Add NaBH4 dropwise to solution

with vigorous stirring until a color change to ‘wine red’ is seen (some

gas will be released).

**IMPORTANT: Initially a color change to dark purple will

be seen. Continue adding NaBH4 beyond

this initial color change until the ‘wine red’ color is achieved. If

the color remains a dark purple despite the addition of more NaBH4 then the colloids have aggregated. To avoid

this, decrease the NaBH4 concentration and add at a slower rate.

It is also important to note that if the TiO2

concentration is too low, or the metal concentration is very high then

aggregation is likely to occur.

- Continue stirring until gas is no longer forming, then top

solution

to desired volume using water with pH adjusted to 1.5 (with HClO4).

Dawson,

A. and Kamat, P. V., Semiconductor-metal nanocomposites.

Photoinduced fusion and photocatalysis of gold-capped TiO2 (TiO2/Au)

nanoparticles. J. Phys. Chem. B, 2001, 105, pp 960-966.

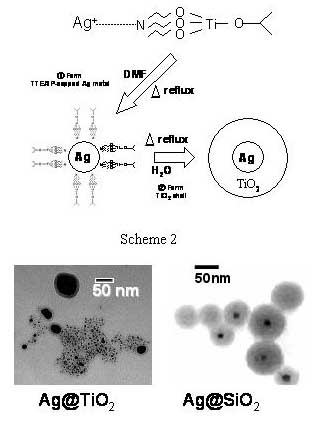

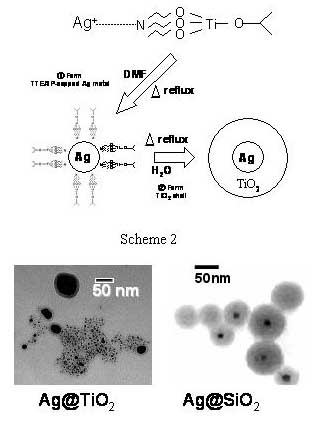

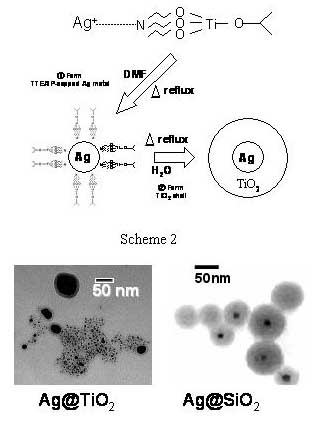

Ag @TiO2 and Ag@SiO2

Colloids.

The synthesis of silver core and TiO2 shell requires

patience and careful optimization of experimental condictions. If not

carefull the TiO2 clusters are formed separately. The method

adopted is as follows

Desired

concentration of TTEAIP (8.3mM, unless otherwise specified) was

prepared in iso-propanol.

Two mL of 15mM AgNO3 solution was mixed with 18mL of TTEAIP

solution. Ten mL of DMF was then added into TTEAIP-Ag solution. The

concentrations of Ag+ and TTEAIP in this solution are 1 mM

and 5mM, respectively.

Desired

concentration of TTEAIP (8.3mM, unless otherwise specified) was

prepared in iso-propanol.

Two mL of 15mM AgNO3 solution was mixed with 18mL of TTEAIP

solution. Ten mL of DMF was then added into TTEAIP-Ag solution. The

concentrations of Ag+ and TTEAIP in this solution are 1 mM

and 5mM, respectively.

The

volume ratio of DMF and i-PrOH has been optimized by carrying out

several batch preparations.

When the amount of DMF was too little or when i-PrOH was excluded,

aggregation

of clusters is observed. The volume ratio of DMF and i-PrOH hence is an

important factor in the preparation of the Ag @TiO2

clusters.

The

solution was stirred first for 15 minutes at room temperature and then

refluxed

with continued stirring. With continued heating of the solution, the

color

slowly changed from colorless to light brown. After 90 min, the color

of the

suspension turned to dark brown. At this point the heating was stopped

and the suspension

was stirred until it cooled down to room

temperature. Thesuspension exhibits a plasmon absorption at 460

nm and shifts to 420 nm upon UV-irradiation in N2 purged solutions.

Silica capped Ag particles

(viz., Ag @SiO2 ) were prepared using active silica

instead

of TTAEIP. The

cluster suspension of Ag@TiO2 and Ag@SiO2 was

centrifuged

and resuspended in ethanol solution. The

procedure was repeated at least 3-times to minimize the content of

water and

DMF in the suspension.

Hirakawa, T. and Kamat, P. V., Electron Storage and Surface

Plasmon Modulation in Ag@TiO2 Clusters. Langmuir, 2004, 20,

5645-5647.

Pastoriza-Santos, I., Koktysh, D. S., Mamedov, A. A.,

Giersig, M., Kotov, N. A. and Liz-Marzan, L. M., One-pot synthesis of

Ag@TiO2 core-shell nanoparticles and their layer-by-layer assembly.

Langmuir, 2000, 16, pp 2731-2735.

Ung, T., Liz-Marzan, L. M. and Mulvaney, P., Controlled

method for silica coating of silver colloids. Influence of coating on

the rate of chemical reactions. Langmuir, 1998, 14, pp 3740-3748.

Desired

concentration of TTEAIP (8.3mM, unless otherwise specified) was

prepared in iso-propanol.

Two mL of 15mM AgNO3 solution was mixed with 18mL of TTEAIP

solution. Ten mL of DMF was then added into TTEAIP-Ag solution. The

concentrations of Ag+ and TTEAIP in this solution are 1 mM

and 5mM, respectively.

Desired

concentration of TTEAIP (8.3mM, unless otherwise specified) was

prepared in iso-propanol.

Two mL of 15mM AgNO3 solution was mixed with 18mL of TTEAIP

solution. Ten mL of DMF was then added into TTEAIP-Ag solution. The

concentrations of Ag+ and TTEAIP in this solution are 1 mM

and 5mM, respectively.