|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

September 3, 2002 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

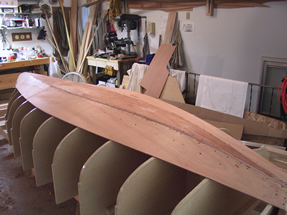

Garboards are lofted and gotten out of 1/4"

1088 occume . Outer edge of the chines are faired to the station molds using

a block and rabbet plane. This allow the garboards to lay flat against the

chines. |

|

|

Some suggest coating the planks with epoxy before

getting out and setting up. I tried this with the garboard but didn't relize

much benifit |

|

|

|

|

|

|

|

|

|

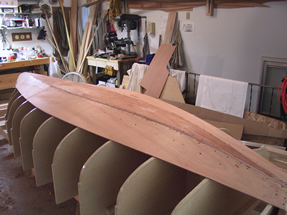

Starboard garboard is attached by

epoxy and screwing to chines and fore and aft to inner stem and transom.

Note the clear plastic tape on the station molds. Prevents gluing the whole

mess to the strongback. Some people use wax. |

|

|

7/8" silicon bronze screws are used along

the chines at about 4.5" intervals. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

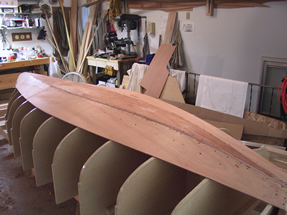

Ends of the garboards are faired

off using a block plane. |

|

|

We made a carboard template for the bottom plank. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fits well. |

|

|

The bottom plank is constructed by epoxying two

1/4" pieces of occume. After epoxy is setup, cut leaving ~ 1/2"

proud. Fitting is done by a lot of planning. |

|

|

|

|

|

|

|

|

Attach bottom plank using 1"

silicon bronze screws and epoxy. Finish by beveling bottom plank edges to

the slope of the garboards. |

|

|

A syringe is used to inject epoxy into any gaps

between bottom plank and garboards. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

HOME |

|

|

|

|

PAGE 4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|