Fund-raisers leading

a building campaign for a new hospital, school, or church often say “It’s

not about a building.” They stress that the structure is simply

a tool to increase the performance and impact of the health care,

education and outreach, or religious activities performed within

its walls. But sometimes it is about a building. Sometimes a building

is the catalyst that sparks a rise to excellence, affecting a neighborhood,

a community, or a world. Fund-raisers leading

a building campaign for a new hospital, school, or church often say “It’s

not about a building.” They stress that the structure is simply

a tool to increase the performance and impact of the health care,

education and outreach, or religious activities performed within

its walls. But sometimes it is about a building. Sometimes a building

is the catalyst that sparks a rise to excellence, affecting a neighborhood,

a community, or a world.

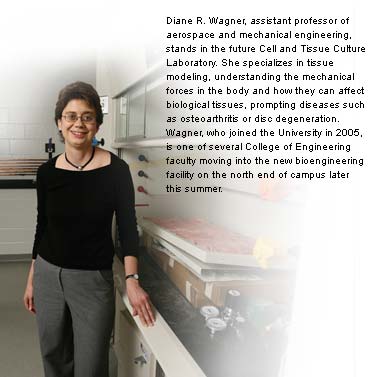

In July 2006 five faculty from the Department

of Aerospace and Mechanical Engineering, one from the Department

of Chemical and Biomolecular Engineering, and their graduate students

and postdoctoral fellows will move from laboratories in Fitzpatrick

Hall to a 25,000-sq.-ft. state-of-the-art facility dedicated to multidisciplinary

research related to biomedical engineering applications.

Located on

the north side of campus next to the Hessert Laboratory for Aerospace

Research, the new building is visible evidence of the commitment

the University has made to biomedical research. “This

is not a me-too program or facility,” says Glen

L. Niebur, associate

professor of aerospace and mechanical engineering. “Although

Notre Dame began biomedical research later than many universities,

we have been very successful in teaming with other institutions, with

medical schools, and with a variety of industry partners nationwide,

including several major orthopedic manufacturers located in Warsaw,

Indiana.“

Lack of a medical school on campus has not affected

the development of the bioengineering program or the building, which

houses laboratories for nano-mechanical characterization, biomaterials

processing and characterization, cell and tissue culture, and tissue

engineering. A tribology laboratory, tissue mechanics lab, manufacturing

area, biomedical imaging lab, and histology and specimen preparation

area are also part of the new facility.

“Moving into a new building is always exciting, particularly

since we [the faculty moving into the facility] were able to work very

closely with the architects to design cutting-edge research space,“ says

Timothy C. Ovaert, professor of aerospace and mechanical engineering.

A key benefit of the new building, according to Ovaert, will be the

synergistic environment created by placing faculty and students who

share common interests together. “We

will be able to focus more on research and interaction with other groups, instead

of logistics.”

Ryan K. Roeder, assistant professor of aerospace

and mechanical engineering, is looking forward to the new space for a number

of reasons. “As

flexible as the space in Fitzpatrick Hall has been, it was not designed

for biomaterials processing or cell and tissue culture,” he says. “I

am also looking forward to having all of my graduate students in the

same space and being able to work closely with them and with other

faculty.” For the past three years Roeder has been partially

utilizing the lab space of JoEllen Welsh, professor

of biological sciences. “Dr.

Welsh has been very generous in allowing us to do all of our cell culture

in her lab space, which puts an added burden on those facilities,” says

Roeder.

Because most of the faculty who will be occupying the new building

hold degrees in more traditional engineering disciplines, questions

they often field include “What can engineers contribute to a

biomedical revolution?” Engineers play a huge role in biomedical

engineering. Combining the traditional strengths of engineers — a

knowledge of materials and mechanical systems, experience in the design

and control of systems, and expertise in materials processing — with

the strengths of biologists and surgeons can impact society. It’s

happening at Notre Dame.

For example, Steven R. Schmid, associate professor

of aerospace and mechanical engineering, and James

J. Mason, formerly

a faculty member and now a researcher at Zimmer, Inc., worked with

the Warsaw, Indiana, based company — a leader in the design,

manufacture, and distribution of orthopedic implants and fracture management

products — to

produce devices that could be used in minimally invasive surgical procedures.

Together, the team pioneered a hip fracture implant featuring curable,

metallic and polymer components that allow for a 25mm surgical incision

instead of the traditional 300mm incision. The new implant and replacement

procedure causes less trauma and promotes a shorter hospital stay and

faster rehabilitation process. Zimmer began clinical trials of the

device in February 2005. With more than 350,000 hip fractures occurring

in the U.S. annually, and approximately four percent of the patients

who undergo hip fracture repair surgery dying during the initial hospital

stay and another 40 percent needing long-term care, the potential impact

is huge.

Similar projects on the horizon for Notre Dame researchers

include a mechanically stable blood substitute, a bioartificial liver

assist device, the development of synthetic bone substitutes, and studies

of microdamage in bone (in relation to osteoporosis and osteoarthritis).

In

addition, the Ernestine Raclin and O.C. Carmichael Jr. Hall, which

houses the Indiana University School of Medicine-South Bend and the

W.M. Keck Center for Transgene Research, was opened in 2005, expanding

collaborative opportunities for engineering faculty.

Much has been accomplished

to date, but much more will be accomplished as faculty continue to

explore the intersection of engineering, biology, and medicine. “Our efforts, which mesh so well with the Catholic

mission of the University,” says Schmid, “will impact the

quality of life as we know it ... in very tangible and direct ways.”

For more information about bioengineering at Notre Dame, visit http://www.nd.edu/~amebio.

|

|

|

|

|

|

Even though the

Notre Dame program in bioengineering is relatively young, many

graduate and undergraduate students who have matriculated from

the Department of Aerospace and Mechanical Engineering are already

contributing to the field of biomedical engineering. They include:

In

2006 Brent S. Mitchell received

a master’s degree in mechanical

engineering with a concentration in biomechanics and biomaterials

from Notre Dame. Today he is an associate research engineer at

Osteotech, a leader in the processing of human bone and connective

tissue for transplantation, as well as biological device systems

for musculoskeletal surgery.

As an undergraduate Casey Korecki worked

in the Tissue Mechanics Laboratory studying the effects of vitamin

D on the mechanical properties of bone growth and strength during

gestation. After receiving her bachelor’s degree in mechanical

engineering in 2003, she entered graduate school at the University

of Vermont, where she is a doctoral candidate in the Department

of Mechanical Engineering.

Jules VanDerSarl received a master’s

degree in mechanical engineering from the University in 2004;

today he is pursuing a doctorate at Stanford University.

Alejandro

Espinoza, who received both a master’s (2003) and

Ph.D. (2005) from the University is a postdoctoral research fellow

in the McKay Orthopaedic Research Laboratory at the University

of Pennsylvania.

The cellular therapies development manager for

Biomet Biologics, Inc., a division of Biomet, Inc., Jim

McKale is responsible for establishing

partnerships with surgeons, research institutes, and corporations;

reviewing research protocols for laboratory, animal, and clinical

studies; obtaining regulatory clearance for products through

the FDA; evaluating intellectual property; and overseeing product

development from concept to market. McKale graduated from Notre

Dame with a bachelor’s

degree in mechanical engineering in 1996.

Audrey Patmore, who

received a bachelor’s degree in mechanical

engineering in 1987, is vice president of global product development

at Zimmer Holdings and one of several alumni who work in the Warsaw,

Indiana, based orthopedic company. |

|