|

|

|

|

|

|

|

|

|

|

|

November 15, 2002 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Overhead pictures showing skeg. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The shear planks were difficult where the bend

around the bilge is more severe. I tried steaming and this helped considerably. |

|

All station molds are unscrewed from the bearers.

Bicycle hooks are installed in the garage rafters and ropes used to lift

and invert the hull. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The combination of the hull and station

molds are quite heavy. The high density particle board by itself is quite

heavy. |

|

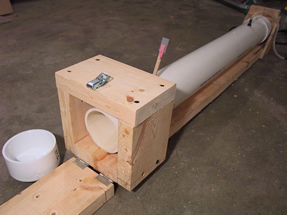

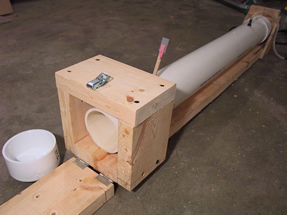

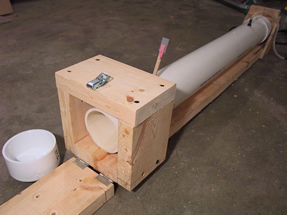

First attempt at a steam box for bending ribs.

The thought was to simply stuff rags in the end. This didn't keep the steam

in the box very well. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

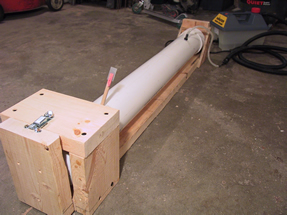

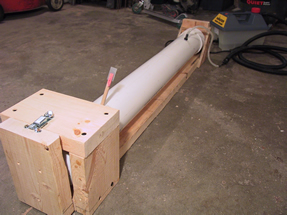

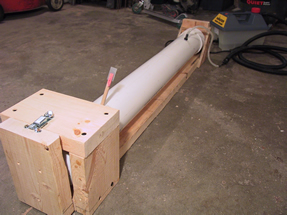

Next attempt was using a 4" PVC pipe with

cap. This worked quite well. |

|

The box with a hinged top on the end is used

to hold the cap on while under pressure. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Instead of building a boiler, I used

a Wagner wall paper removal steamer. The handle is removed and a piece of

Tygon tube connects the boiler to the PVC pipe. A little weight on top of

the pressure will build a pretty darn impressive pressure inside the tube. |

|

One station mold removed in preparation of bending

the first set of ribs. Kayla can't wait. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

First set of ribs bent in. More on this in later

pages. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Probably a good idea to only unscrew

and remove one station mold at a time while installing ribs. This should

help preserve the hull shape. |

|

A mortise is cut into the chines to accept the

end of the ribs. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The mast is constructed by selecting

straight, clear 2" X 4" X 12' lengths of pine. The pieces are

ripped and ran through an edge jointer. |

|

Epoxy is used to laminate the pieces to a size

that a 3" diameter mast can be gotten out. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Because the tops of the station molds

are straight and plum, they are used as a flat surface to clamp the mast

pieces together. |

|

The mast is first eight sided using a tablesaw. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A jig is made along the length of a workbench

a little bit longer than the mast. It will be used to hold the mast flat

while planing. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

HOME |

|

|

|

PAGE-6 |

|

|

|

|

|

|

|

|

|

|

|

|