Facilities

Packaging Equipment

- DISCO Automatic Grinder (DAG 810) Model 810

- Manufacturer:

DISCO Corporation - Operating Instructions

Description

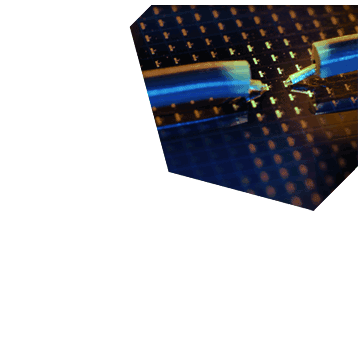

The Disco Automatic Grinder (DAG 810) Model 810 is a single-spindle/single-chuck-table unit that performs back-side grinding on samples. The users perform work-piece loading and unloading manually at the front of the machine. The machine can grind silicon and other semiconductor substrates. It can also grind high-load, hard-to-process ceramics and crystals. The DAG 810 can handle small pieces (mounted on a thermal release backing tape) or standard 4”, 6”, or 8” inch wafers.

Allowed Materials

Si, Ge, C, GaAs and its compounds, InP and its compounds, cleaned SiO2 (glass), and cleaned Al2O3 sapphire.

Prohibited Materials

Metals and organics (resist, BCB, polyimide, epoxy, tape, vacuum grease, rubber, plastic, etc.)

Cleaning procedure

Samples should be free of greases, oils, fingerprints, and particles. If necessary, samples should be cleaned in solvents, followed by DI rinse and N2 blow dry. Particular attention should be paid to the back side of the sample.

Contact Information:

For additional information, please contact the NDNF Staff at pfay@nd.edu.

9.04.15