Facilities

Metrology Equipment

- Gaertner Ellipsometer

- Manufacturer:

Gaertner Scientific Corporation - Operating Instructions

Description

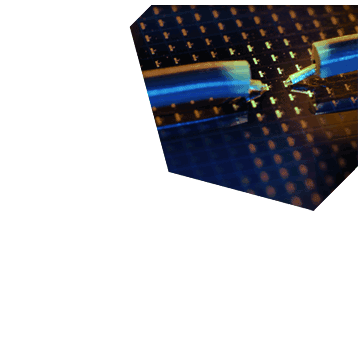

Ellipsometric measurements involve illuminating the surface of a sample with monochromatic light (HeNe laser at 6328 angstroms) of known wavelength and polarization and then analyzing the polarization state of the reflected light. The light is along a fixed path or angle of incidence. The L117 Ellipsometer has provisions for precise, pin-located setting of the angle of incidence between 45 and 90 degrees, although 70 is most commonly used.

For measurement purposed, the angle of reflection is set at the same angle as the angle of incidence. With the angle set their respective optical axis intersect the vertical centerline at the same point. The height of the sample stage is adjusted such that the point of intersection of the incidence and reflective occurs on the surface of the material sample situated on the stage and that the sample surface is normal to the vertical centerline of the plane of incidence.

Upon illuminating the surface of the test sample, the reflected light, with its polarization altered by the properties of the sample, passes through the analyzer and an optical interference filter.

Interpretation of the data yields the optical constants of the material or, if the material surface is film-covered, the thickness and optical constants of the film.

Allowed Materials

Semiconductor materials, dielectrics, and thin metal films (< 100 nm).

Prohibited Materials

Liquids of any kind.

Cleaning procedure

Samples to be used in the metrology equipment should be free of greases, oils, fingerprints, and particles. If necessary, samples should be cleaned in solvents, followed by DI rinse and N2 blow dry. Particular attention should be paid to the back side of the sample.

Contact Information:

For additional information, please contact the NDNF Staff at pfay@nd.edu.

7.12.17