Facilities

Deposition Equipment

- Perkin-Elmer 2400 Sputtering System

- Manufacturer:

Randex - Operating Instructions

Description

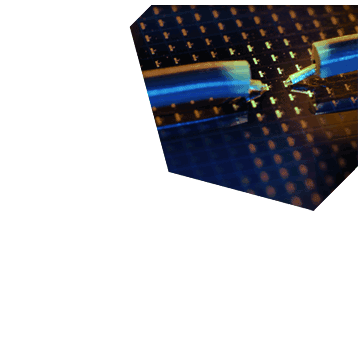

The Randex Model 2400-8SA sputtering system is designed to deposit a wide variety of materials onto substrates such as ceramics, metals, plastics, glass, and semiconductors. The resulting thin films can range in thickness from a few Angstroms up to a fraction of a millimeter. This sputtering system can deposit in sequence up to three different materials onto a single substrate, thereby creating a sandwich-structured film such as multilayer optical interference filters. The system can also be used for ion etching, a process in which material is removed from, rather than deposited on, the substrate.

The Sputtering Process

Sputtering is a momentum transfer process in which atoms from a

cathode/target are driven off or sputtered by bombarding ions.

In this process, the momentum of bombarding ions is more important

than their energy. For example, a hydrogen or helium ion accelerated

to 3,000 eV will cause very little sputtering compared to an

ion of argon (which is chemically inert) with the same 3,000

eV energy, simply because the lighter hydrogen or helium ion

has much less momentum. Sputtered atoms travel until they strike

a substrate, where they deposit to form the desired layer. As

individual atoms they are chemically active and readily form

compounds with the ions and atoms of the bombarding gas. For

this reason inert argon is used as the bombarding gas. In some

applications however, a reactive gas is purposely added to argon

so that the deposited film is a chemical compound, and not the

elemental target materials. When argon ions strike the target

their electrical charge is neutralized and they return to the

process as atoms. If the target is an insulator, the neutralization

process results in a positive charge on the target surface. This

charge may reach the level where bombarding ions are repelled

and the sputtering process stops. To continue the process the

polarity must be reversed to attract enough electrons from the

discharge to eliminate surface charge. This periodic reversal

of polarity is done automatically by applying RF voltage onto

the target assembly (hence the term RF sputtering). Of interest

here is the diode rectifier-like behavior of the target and discharge

system. This is caused by the vast difference in mobilities of

ions and electrons; the electrons, which are much lighter, are

attracted in much greater numbers to the target during their

positive half-period of RF voltage than are the heavy ions during

their half-period.

Film types available: Cu, Ti, Ta, W, SiO2, AlSi, Cr, and 7059 glass.

Contact Information:

For additional information, please contact the NDNF staff at pfay@nd.edu.

2.10.15