A Creative Bent

An extremely technical discipline, engineering is also an extremely

creative one. Engineers are naturally curious about the way things

work. They are equally as passionate about making them work better.

That’s exactly what seniors are challenged to do in capstone

courses throughout the College of Engineering.

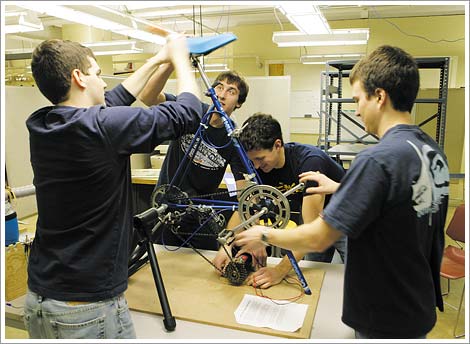

For example,

last semester mechanical engineering majors were asked to design and construct

a working prototype of one of four products: a basic ambulatory assistance system;

an innovative musical instrument; an automated circuit board assembly, solder,

and test system; or a human-powered potable water still, which could also be

entered in the 2007 American Society of Mechanical Engineers Student Design Contest.

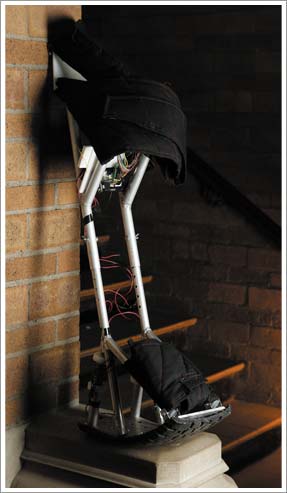

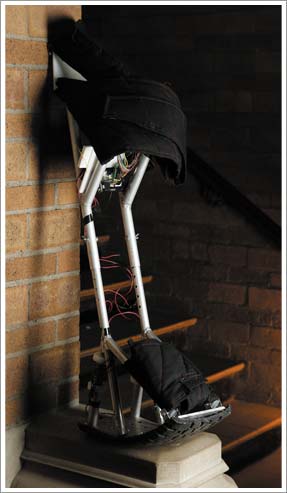

The

goal of the ambulatory assistance device was to help an able-bodied

individual who had sustained a knee, ankle, or foot injury maintain

as much mobility and independence as possible during the recovery

process. Teams opting to pursue this type of device needed to design

a low-cost, all-weather product that was more sophisticated than

crutches, more compact than a golf cart, and more flexible than a

wheelchair.

|

|

<< A basic ambulatory

assistance system was developed by the Leg O’Maniacs — Vanessa

Carr, Kim Dueffert, Mike Hennig, Eileen Jackson, Steve Klein, and

Dan Turnure. |

|

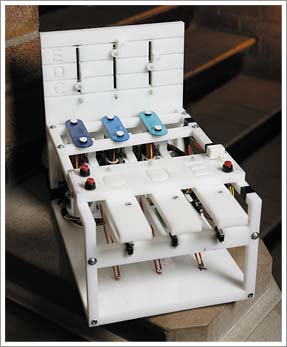

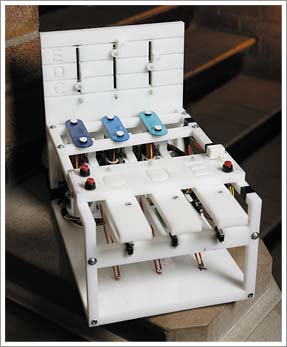

<< Gordon Farmer, Mike Johnson, Eric Laumann,

Bryan Marek, and Phil Moss developed the Mini Mozart, an interactive

keyboard for 3- to 6-year old children. |

|

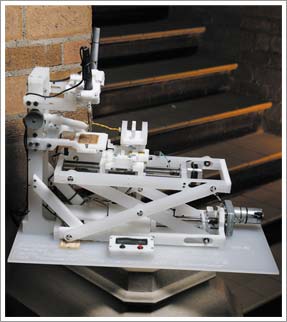

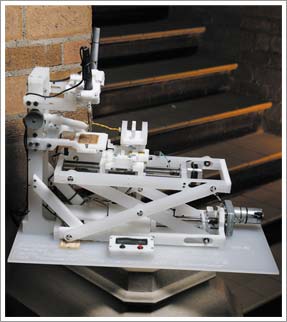

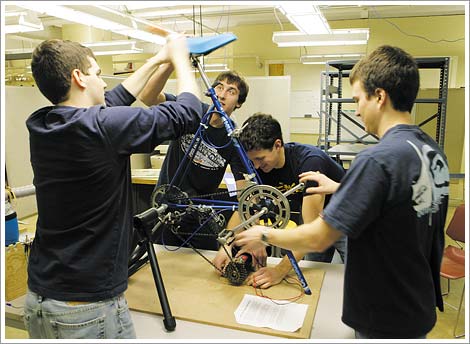

<< According to team members Nicholas Frohmader,

Jeff Lammermeier, Mike Lavery, Dave Rowinski, and Brad Shervheim, SolderBaat

grabs a circuit element, transports it to a board, and makes a precise

soldered connection, while providing the operator feedback throughout

the process. |

One of the challenges for

teams designing an innovative musical instrument was to integrate

their musical interests with their engineering skills. The “product” needed

to be able to play a range of tones (or notes) both manually and

in an automated fashion, similar to a player piano. In their final

presentations, some of the teams suggested that their devices could

help teach children to read and play music or provide motor skill

rehabilitation (enhance dexterity) for disabled patients.

Falling under the category of automated fabrication and robotic-enhanced devices,

students could also choose to design a device that would take a component from

a cartridge, position it on a circuit board, and solder it in place. The device

would then test the integrity of the final board and display the state of the

board to the operator.

The fourth product involved the creation of a human-powered water distillation

system that could be used by disaster victims, the military, and developing countries

where water supplies might be suspect. While design parameters included that

the final product needed to be compact, easily transported, durable, and easy

to operate, the most important aspect of the device was that it could boil, distill,

and supply potable water to the user, who would power the device.

After a few minor adjustments, Team InnovationNDistallation — Dan

Driscoll, Michael Giordano, Kevin Hederman, and Todd Ptacek — plans

to enter their emergency water recovery system in the 2007 ASME Design

Contest.

|

|