Facilities

Metrology Equipment

- Alpha-Step 500 Profiler

- Manufacturer:

Tencor - Operating Instructions

Description

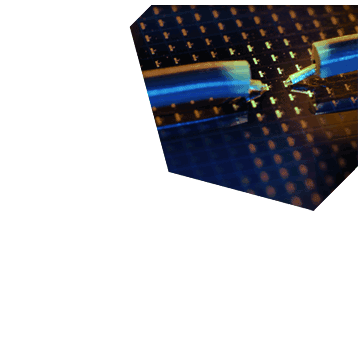

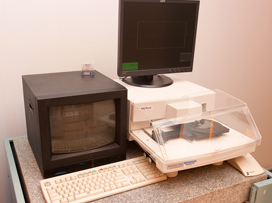

The Alpha-Step 500 Profiler is a computerized, high-sensitivity surface profiler that measures roughness, waviness, and stop height in a variety of applications. It features the ability to measure micro-roughness with up to 1A (0.004 min.) resolution over short distances as well as waviness over a full, 10-mm (0.4-in.) scan. The Alpha-Step 500 can profile a variety of materials, including: Magnetic disks, Semiconductor wafers, Precision-machined and polished surfaces, Ceramics for micro-electronics, Glass for flat panel displays & Optical surfaces

The Alpha-Step 500 provides the following features: Measurement of vertical features ranging from under 100 A (0.4 min.) to approximately 0.3 mm (12 mils), with a vertical resolution of 1 or 25A (0.004 or 0.1 min.). Measurements can be taken in either metric or English units, which are selectable independently for horizontal and vertical parameters. Up to 5000 data points per profile guarantee that the horizontal resolution is generally limited by the stylus radius and not by the number of data points. Measurement of many roughness and waviness parameters with roughness and waviness separated by user-selectable cutoff filters. A band pass filter allows the separation of intermediate wavelengths. Ability to fit and level data, allowing accurate measurements on curved surfaces. Ability to detect the edge or apex of a profile artifact, allowing precise comparison of data measured on similar samples. Ability to segment a length into multiple scans as in the OD-to-OD profile of a disk with a center hole. Ability to repeat a scan up to ten times and automatically calculate the average, thereby minimizing the effects of environmental noise on measurements. Many ease-of-use features, including color screens with pull-down menus and pop-up windows, and trackball control of measurement cursors and stage position (optional Motorized Stage only). The Alpha step can also accommodate samples up to 150 mm (6 in.) wide and 15 mm (.59 in.) thick.

Allowed Materials

Si, Ge, C, GaA,s and its compounds, InP and its compounds, cleaned SiO2 (glass), cleaned Al2O3 (sapphire), Au (gold), Al (aluminum).

Prohibited Materials

Organics, greases, and other substances that may contaminate the stylus.

Cleaning procedure

Samples to be used in the metrology equipment should be free of greases, oils, fingerprints, and particles. If necessary, samples should be cleaned in solvents, followed by DI rinse and N2 blow dry. Particular attention should be paid to the back side of the sample.

Contact Information:

For additional information, please contact the NDNF Staff at pfay@nd.edu.

03.28.16