Facilities

Lithography Equipment

- Cobilt Model CA-800

Wafer-to-Mask Alignment and Exposure System - Manufacturer:

Cobilt - Operating Instructions

Description

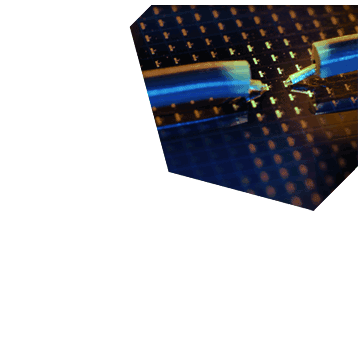

The Cobilt Model CA-800 Aligner is designed to allow the operator to accurately align a wafer to a mask and then expose the wafer to a source of ultraviolet light. The Aligner operates as a semi-automatic device, which requires the operator to align the wafer to the mask as well as initiating the wafer to mask contact an exposure sequence.

In the normal process, the wafer, coated with a photo-sensitive solution, is pre-aligned on the front chuck. The wafer and chuck are then rotated into alignment position by a turntable which supports the chuck. A piston raises the wafer and chuck up to the mask and then lowers the wafer to an adjustable separation distance. The operator then aligns the wafer to the mask, using the optical system and a micromanipulator control.

Buttons on the micromanipulator initiate coarse or fine alignment modes and contact and separate states.

When the wafer has been aligned to the mask the wafer in intimate contact with the mask and wafer are exposed to an ultraviolet light source. The intensity or spectrum of the light source can be varied by selecting appropriate filters and inserting them into the filter holder. The exposure time is controlled by an adjustable digital timer.

Allowed Materials

Si, Ge, C, GaAs and its compounds, InP and its compounds, cleaned SiO2 (glass), and cleaned Al2O3 (sapphire).

Prohibited Materials

Iron, organics, liquids, and greases.

Cleaning procedure

Samples to be used in the lithography equipment should be free of greases, oils, fingerprints, and particles. If necessary, samples should be cleaned in solvents, followed by DI rinse and N2 blow dry. Particular attention should be paid to the back side of the sample.

Contact Information:

For additional information, please contact the NDNF Staff at pfay@nd.edu.

06.26.15