Facilities

Lithography Equipment

- GCA AutoStep 200 i-Line Wafer Stepper

- Manufacturer:

GCA - Operating instructions

- Job preparation

Description

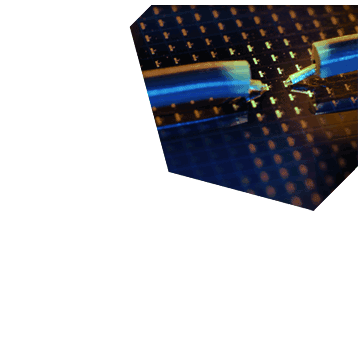

The AutoStep 200 lithography system is a 5x reduction, production grade i-stepper with repeat exposure capabilities as large as 17 mm x 17 mm. The system uses a 700W Hg arc lamp to produce 365 nm light at ~275 mW/cm2 intensity. The system features a fully automatic reticle management system (RMS) that loads/unloads with a built in bar code scanner. The RMS system will automatically align to the stage that is house in a climate-controlled system to eliminate system drift due to thermal instabilities. The system can process 4" wafers or samples as small as 10 mm x 10 mm. Manual wafer loading is achieved through one of several chucks that set the depth of focus for the exposure. The system can easily produce 0.5 um isolated lines across the entire field using a wafer autoleveling system. Bi-weekly calibration of the stage ensures global alignment better than 0.3 um for manual aligned wafers. Using the die x die, u-DFAS local alignment system, alignment errors better than 0.10 um are easily achieved.

Allowed Materials

Semiconductor-based materials, dielectrics, metal films, and resists.

Prohibited Materials

Organics, liquids of any type, greases.

Cleaning Procedure

Samples generally do not require special cleaning, unless needed to remove prohibited materials before processing. All materials to enter the equipment will be handled with wafer tongs by an operator wearing latex, poly, or nitrile clean gloves.

For additional information, please contact the NDNF staff at pfay@nd.edu.

1.06.16