Facilities

Lithography Equipment

- GCA Mann 3600F Photomask Pattern Generator

- Manufacturer:

RTS Technologies - Operating Instructions

Description

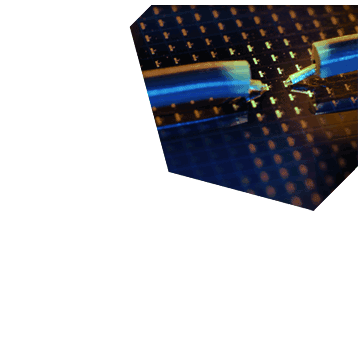

The GCA Mann3600F pattern generator is capable of producing standard 5" x 5" (0.090" thick) or standard 4" x 4" (0.060" thick) chrome mask plates for use in optical lithography. The system is capable of creating mask features to as small as 2 um in size. The masks are originally designed in the L-Edit CAD system and then converted into a format that can be manipulated into data read by the pattern generator. The light source for pattern exposures is a mercury arc lamp that is filtered and projected onto a shutter, which controls the exposure time. A set of aperture blades (vertical and horizontal) can be rotated from 0 to 90 degrees in 0.1 degree increments to create rectangular images of varying sizes and orientations to form the pattern design. The system is contained in a temperature controlled climate to minimize environmental effects during the mask generation. The system can create masks at 1x for contact lithography or custom shrinks (typically 5x and 10x) for reduction lithography. Normal exposure rates for the mask making process are around 2000 to 3000 exposures per hour.

Allowed Materials

Semiconductor-based materials, dielectrics, metal films, and resists.

Prohibited Materials

Magnetic materials, organics, epoxy, rubbers, and plastics. Substances that can outgas/sublime/evaporate in vacuum; hydrocarbons (oil, grease, fingerprints); organic materials; liquids of any kind.

Cleaning procedure

Samples generally do not require special cleaning, unless needed to remove prohibited materials before processing. All materials to enter the equipment will be handled with wafer tongs by an operator wearing latex, poly, or nitrile clean gloves.

Contact Information:

For additional information, please contact the NDNF Staff at pfay@nd.edu.

05.28.15