Facilities

Lithography Equipment

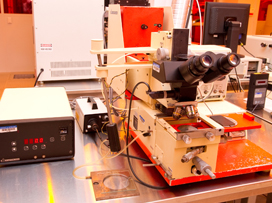

- SUSS MJB 3 Mask

Aligners (2) - Manufacturer:

SUSS MicroTec - Operating Instructions

Description

The SUSS MJB 3 Mask Aligner is designed for high resolution photolithography in a laboratory or pilot production environment. The MJB 3 offers unsurpassed flexibility in the handling of irregularly shaped substrates of differing thicknesses, as well as standard size wafers up to 3” diameter.

The SUSS MJB Standard is equipped with a 200W lamp housing containing a relatively simple and yet comparatively high resolution optical system. A 200W mercury short-arc lamp is used. Primary exposure wavelengths are 350-500nm. The aligner performs exposures in hard contact mode (nitrogen pressure under the substrate) and soft contact mode (vacuum under the substrate). As an option, the MJB 3 Standard can also be equipped to perform proximity exposures. Line/space resolution of 1.5 microns and alignment accuracies of 0.2 microns can be obtained with the MJB 3.

Allowed Materials

Si, Ge, C, GaAs and its compounds, InP and its compounds, cleaned SiO2 (glass), and cleaned Al2O3 (sapphire).

Prohibited Materials

Indium, tin, zinc, iron, and organics (vacuum grease, rubber, plastic).

Cleaning procedure

Samples to be used in the lithography equipment should be free of greases, oils, fingerprints, and particles. If necessary, samples should be cleaned in solvents, followed by DI rinse and N2 blow dry. Particular attention should be paid to the back side of the sample.

Contact Information:

For additional information, please contact the NDNF Staff at pfay@nd.edu.

06.26.15