Facilities

Lithography Equipment

- Tamarack Series 142 Contact Printer

- Manufacturer:

Tamarack - Operating Instructions

Description

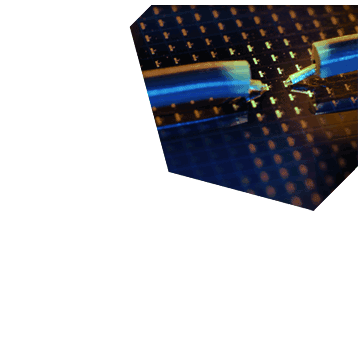

The Tamarack Series 142 Contact Printer provides production replication of hard surface photomasks (chrome, black chrome, iron oxide, silicon) and soft surface photomasks (emulsion, diazo) ranging from 2”x 2” to 5”x 5”. High-speed evacuation and short cycle times are provided by a unique printing chamber which holds the master and copy separated during evacuation.The Tamarack Collimated Exposure Source provides high resolution with minimum variation in the geometry. This source produces a carefully controlled collimated light of very high quality.Overall operation of the printer can be either manual from the front control panel or automatic via the adjustable time delay relays as built into the system.Tamarack Contact Printer. The Tamarack Series 142 Contact Printer provides production replication of hard surface photomasks (chrome, black chrome, iron oxide, silicon) and soft surface photomasks (emulsion, diazo) ranging from 2”x 2” to 5”x 5”. High-speed evacuation and short cycle times are provided by a unique printing chamber which holds the master and copy separated during evacuation.The Tamarack Collimated Exposure Source provides high resolution with minimum variation in the geometry. This source produces a carefully controlled collimated light of very high quality. Overall operation of the printer can be either manual from the front control panel or automatic via the adjustable time delay relays as built into the system.

Allowed Materials

Lithography photomasks only.

Prohibited Materials

Everything except photomask materials.

Cleaning procedure

Samples to be used in the lithography equipment should be free of greases, oils, fingerprints, and particles. If necessary, samples should be cleaned in solvents, followed by DI rinse and N2 blow dry. Particular attention should be paid to the back side of the sample.

Contact Information:

For additional information, please contact the NDNF Staff at pfay@nd.edu.

06.26.15