Facilities

Deposition Equipment

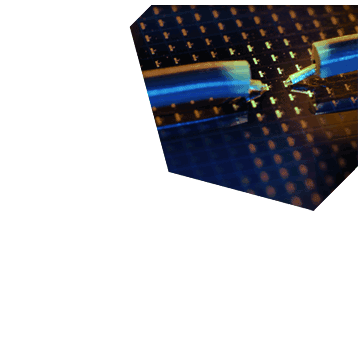

- Veeco Evaporator

- Manufacturer:

Veeco Instruments

Description

The unit is used for thermal vacuum deposition of Al or Cr to the substrates situated some 30 cm above the evaporating metals and provides means for multiple-angle evaporation, controlled oxidation (including plasma oxidation), and in situ electrical characterization. It features:

- The rotation mechanism to deposit metals at angles within the range of ±10 degrees with respect to the normal to the plane of the wafer. The rotation is implemented through mechanical gear mechanism and the rotation angle is measured using a special angle monitor with resolution of 0.1 degree.

- Water-cooled wafer holder to prevent the change in temperature of the substrate during the evaporation. Temperature of the substrate could be continuously monitored during the evaporation.

- Low-power DC plasma source for pre-deposition cleaning and controlled plasma oxidation of deposited metals

- The combination of leak valve and a needle valve to provide precise amount of oxygen into the chamber. Two regimes of oxidation are possible: controlled flow of O2 for the oxidation during the deposition and constant pressure oxidation of already deposited materials

- Special test fixture to perform in situ electrical measurements during the deposition of metals

- Mechanically controlled shutter and crystal thickness monitor, vacuum control system, mechanical and diffusion pumps

- Base pressure (with N2 cooled trap) is below 5x10-7 torr

Contact Information:

For additional information, please contact the NDNF Staff at pfay@nd.edu.

2.10.15